One moment please...

One moment please...

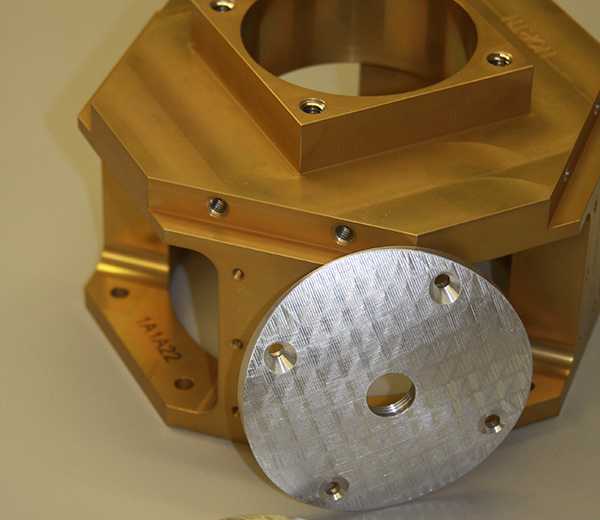

Group Manufacturing Services, Inc. is your trusted partner for a wide range of precision manufacturing services.

From precision sheet metal fabrication to robotic welding, we deliver top-quality solutions for all your manufacturing needs.

With our expertise in CNC machining, rapid prototyping, product design, engineering, laser cutting, and more, we are committed to providing you with the highest service and satisfaction.

Explore the pinnacle of manufacturing innovation at GMS. Whether you seek precision CNC machining, custom sheet metal fabrication, advanced electro-mechanical assembly, laser cutting expertise, or streamlined JIT fulfillment services, we are your one-stop solution.

“Good company to work with, amazing with sheet metal!”

“They are very professional, consistent, responsive to your needs, and have been known to work many production miracles for our company.”

“GMS is a world-class sheet metal fabricator and machine shop right here in the heart of Tempe/Phoenix.”

“Best place to go for fabricated parts, powder coating with great pricing and turnaround times.

Very nice to work with.”

Group Manufacturing Services, Inc. (or GMS) is a precision parts manufacturer located in Tempe, AZ. We specialize in sheet metal fabrication and CNC fabricated products across a wide variety of very specialized industries. GMS has proudly been a Tempe, AZ resident for over 30 years, and in that time we have learned quite a bit about the sheet metal manufacturing industry and its clients.

Group Manufacturing Services, Inc. has been manufacturing in Arizona for over 30 years. At GMS we feel there are 3 qualities or disciplines that set us apart from our competitors, let’s take a look at those ideals and reveal a little about our formula for success in the precision machining market. Do you have an […]

In the metal finishing industry as with any other retailer, the saying goes “The customer is always right.” Popularized at the turn of the century, this statement embodies the philosophy that customers should not be cheated or deceived. Group Manufacturing Services has embraced this idea for over twenty years while working with a wide spectrum […]